Waste bread amazake

This is part of our series on upcycling bread by-products.

Table of Contents

i. Introduction

Amazake is a sweet and creamy Japanese fermented beverage, usually made with rice, water and either sake lees (for an alcoholic version) or kōji (for a non-alcoholic version).¹ Here we have adapted the latter method to use stale bread. The kōji produces amylases that break down the bread's starches into simple sugars (glucose and maltose) to make a sweet, aromatic, malty bread porridge that can be served as is, or blended for a smoother texture. Alternatively, it can be strained through a muslin cloth to yield a versatile honey-like syrup that can be used in all sorts of potential applications, such as a topping for pancakes, or as a flavouring in ice creams or other desserts. The solids could then potentially be used for other applications, for example as an enzymatic marinade akin to shio kōji.

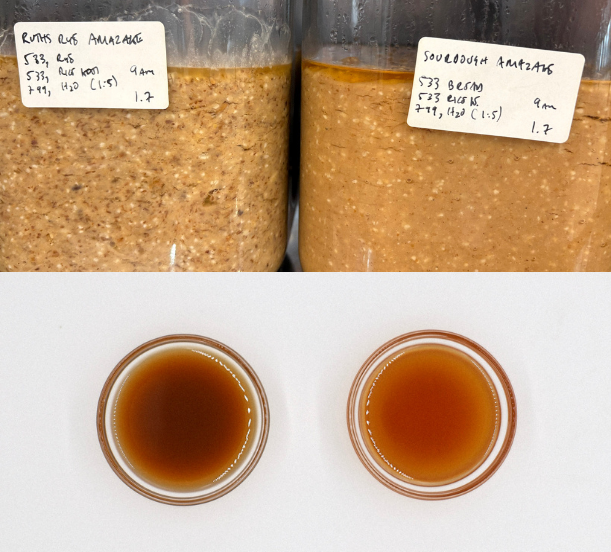

This recipe works with all sorts of different breads, each of which yields a sweet, creamy beverage with slightly different flavours. The rye bread amazake that we made had notes of raisins, autumnal fruits and maltiness, whereas the sourdough amazake had notes of caramel and grapes.

ii. Recipe

Ingredients

1 part stale bread, cut into uniform 2cm pieces

1 part boiling water

1 part rice kōji, fresh or frozen

Method

Place the bread in a large heat-proof vessel and pour over the boiling water to sterilise the bread, helping control for undesired microbial growth.

Use a temperature probe to check the temperature of the bread–water mixture. Once it has dropped to 65°C², add the rice kōji and blend using a hand blender to achieve a smooth, consistent mixture.

Sterilise a large fermentation vessel with a sealable lid using alcohol or boiling water. Allow to evaporate if the former, and to cool if the latter. Pour in the bread–water–rice kōji mixture and seal with a lid.

Place the fermentation vessel in a heated incubator set at 60°C or a precise oven for 12 hours to allow the mixture to ferment.

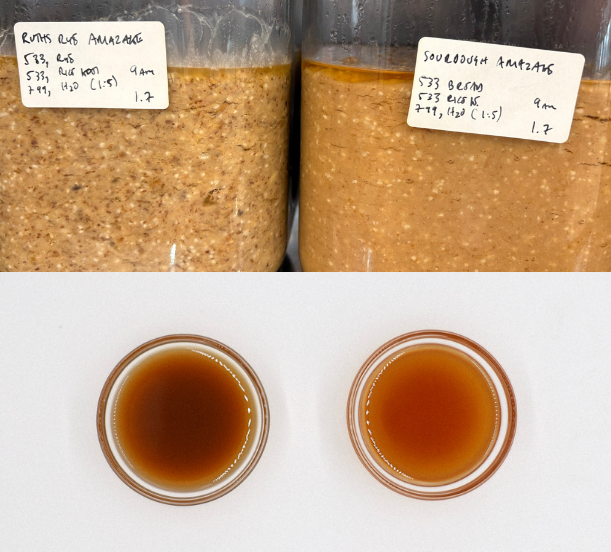

Once fermentation is complete, the bread amazake can either be used as it is, blended into a smooth purée, or the mixture can be strained through fine muslin cloth, or centrifuged, to separate the solids and the liquid, reserving the latter for use as a sweet liquid ingredient (the former can also be used elsewhere). In any form, the amazake can be refrigerated for up to 1 week or frozen for longer storage. Refrigeration and freezing slow down but do not completely stop the microbial and enzymatic activity. A shelf-stable product can be achieved in different ways: we chose to seal the amazake in an airtight jar or vacuum bag and heat in a water bath or steam at 90°C for 40 minutes to pasteurise, denature enzymes and arrest further activity.³

Centrifuged sourdough amazake (left) and its solid by-product (right)

iii. Adaptations

This recipe works with all sorts of different breads, each of which yields slightly different flavours. Why not experiment with different breads and see how each brings its own unique character to amazake?

Contributions & acknowledgements

Kim performed the original culinary research, with further testing conducted by Nurdin, who documented the process with notes and photography. Eliot wrote the article using these notes and following further discussion with Nurdin and Kim, with contributions and editorial feedback from Josh. Eliot and Nurdin photographed the final product in our food lab.

Related posts

Endnotes

[1] For a more in-depth introduction to amazake see: Amazake (Fermented Japanese Rice Drink) 甘, Just One Cookbook.

[2] Cooling the bread-water mixture to 65°C ensures that once the rice kōji is added, the temperature will drop to around 60°C, which is optimal for koji’s amylase activity; is hot enough to suppress unwanted microbial growth; and elimintates the need for reheating in the incubator.

[3] Note that this method of heat treatment can change the flavour profile of the end product. You can use a different, more precise pasteurisation method (e.g. 72˚C internal temp for 15 seconds) if you have access to specialist equipment and prefer to do so.